This technique requires sufficient knowledge about the process and its parameters including their effect on the component’s mechanical characteristics. The result proved that quality of products can be improved by using the DOE approach.įused deposition modelling (FDM) is an additive-based manufacturing technique used by various industries due to its effectiveness & ability to make complicated geometries possible. Finally, from the optimization plot, the validation error between the prediction value and experiment was 1.72%. The comparison defect quantity analysis between current companies setting with the optimum setting showed improvement by 21% reduction of defect quantity at the optimum setting. The results of the study showed that the optimum parameter setting that could reduce the defect quantity of preform was MHR= 88☌, CT1= 24☌ and CT2= 27☌. The collaboration enabled the researchers to collect the data and also help the company to improve the quality of its production. This study involved a collaboration with a preform injection moulding company which was Nilai Legasi Plastik Sdn Bhd.

Next, from the model, 95% confidence level (p-value) was considered and the significant parameter was figured out. In order to interpolate the experiment data, mathematical modeling was used which consists of different types of regression equation. The relationship between input and output of the process was analyzed using regression method and Analysis of Variance (ANOVA). Meanwhile, the output for the process was defects quantity of the preform. The selected input parameters were mould hot runner temperature, water cooling chiller temperature 1 and water cooling chiller temperature 2.

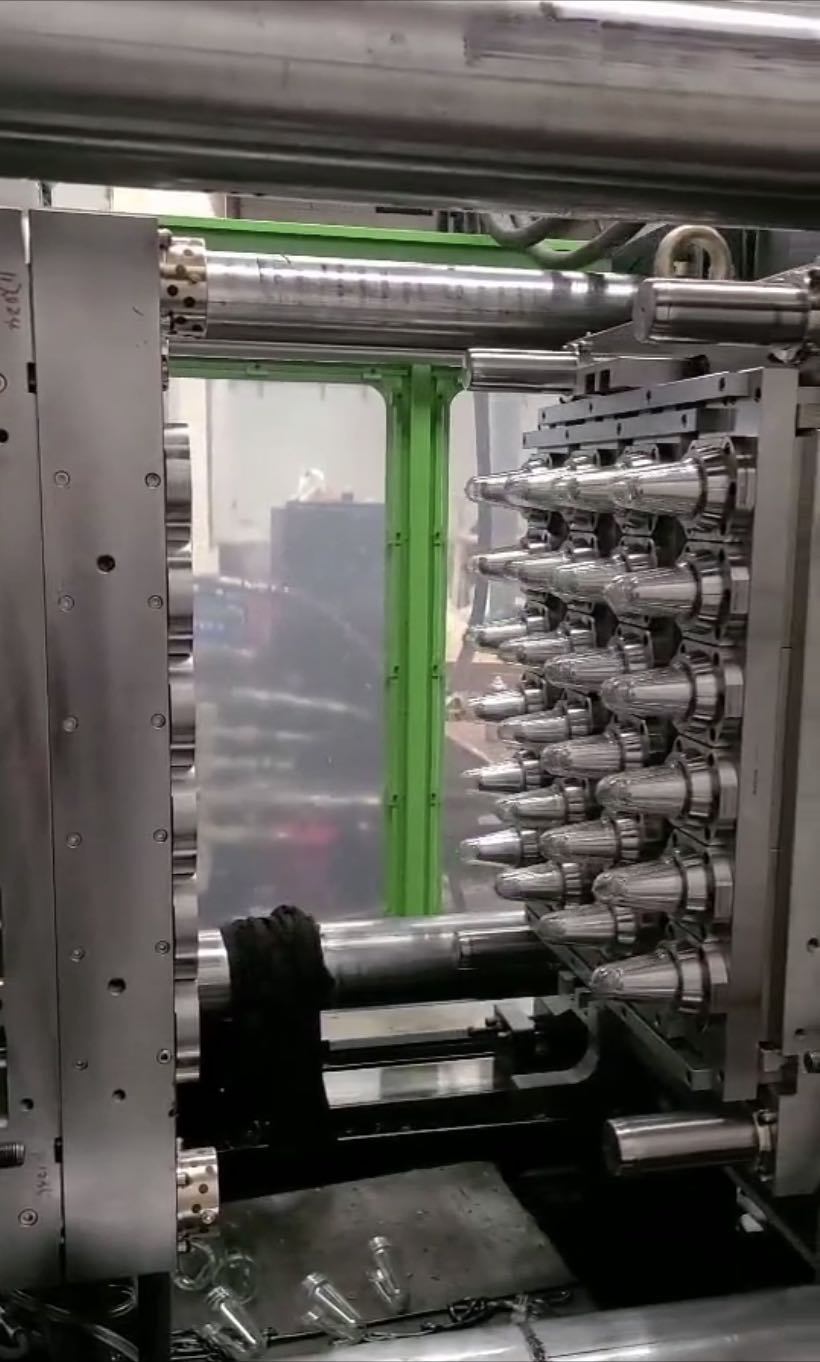

Pet preform manufacturing software#

In this case study, Minitab 17 software was used to analyses the data. Design of Experiment (DOE) by factorial design approach was used to find an optimum parameter setting and reduce the defects. Optimizing the parameter of injection moulding process is critical to enhance productivity where parameters must operate at an optimum level for an acceptable performance. In this study, the effect of injection moulding parameter on defects quantity of PET preform was investigated. The quality of product in injection moulding is influenced by injection moulding process parameter.

Quality control is an important aspect in manufacturing process.

0 kommentar(er)

0 kommentar(er)